Meet WIRAS

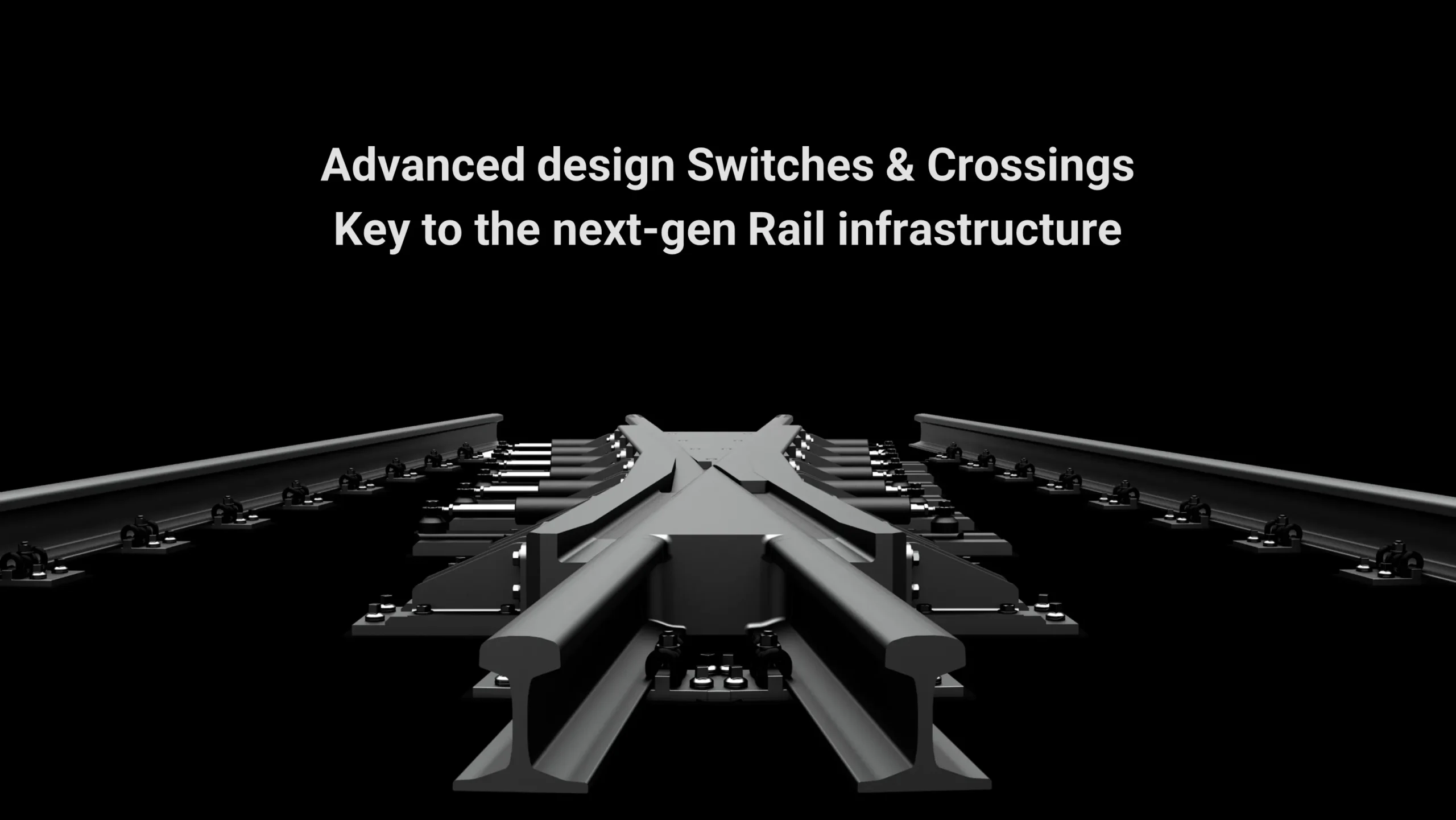

The WInterproof RAilway Switch

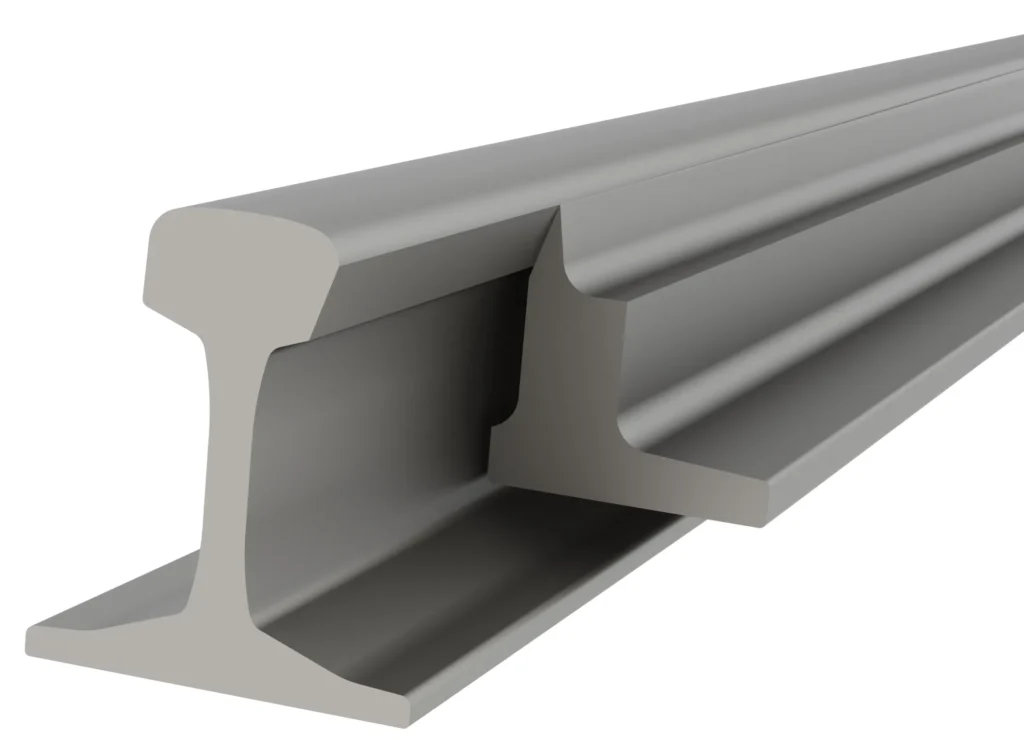

along with its winterproof movable frog is a completely new take on railway switch technology. Designed, developed, and made in the Netherlands, it has a mechanical setup unlike anything used on railways today.

What makes it special?

It doesn’t need heating systems to stay reliable in cold, snowy, or icy conditions. That means no point heating, no movable frog heating, extremely low energy use, and zero CO₂ emissions. That’s a big win for both reliability and the environment.

Why Change the Switch?

The basic idea behind today’s railway switches goes all the way back to 1832, invented by Charles Fox when trains were short, light, and slow. But modern rail traffic is a different story.

Heavier trains, higher speeds, and way more of them. Yet the switch, one of the most critical and fragile parts of the rail network, hasn’t really changed.

Until now.

The WIRAS Innovation

The WIRAS switch is a bold, smart and totally new design.

An out-of-the-box solution to the many issues rail systems face today. It challenges the old way of thinking in the railway industry, but it’s gaining traction. More and more experts are recognizing it as a promising solution for the future of rail transport.

Facts and Figures (per switch)

Winterproof by Design

- No switch tongues or frog points that move horizontally, a major advantage in snowy and icy conditions.

- Resistant to snow and ice, eliminating the risk of winter malfunctions.

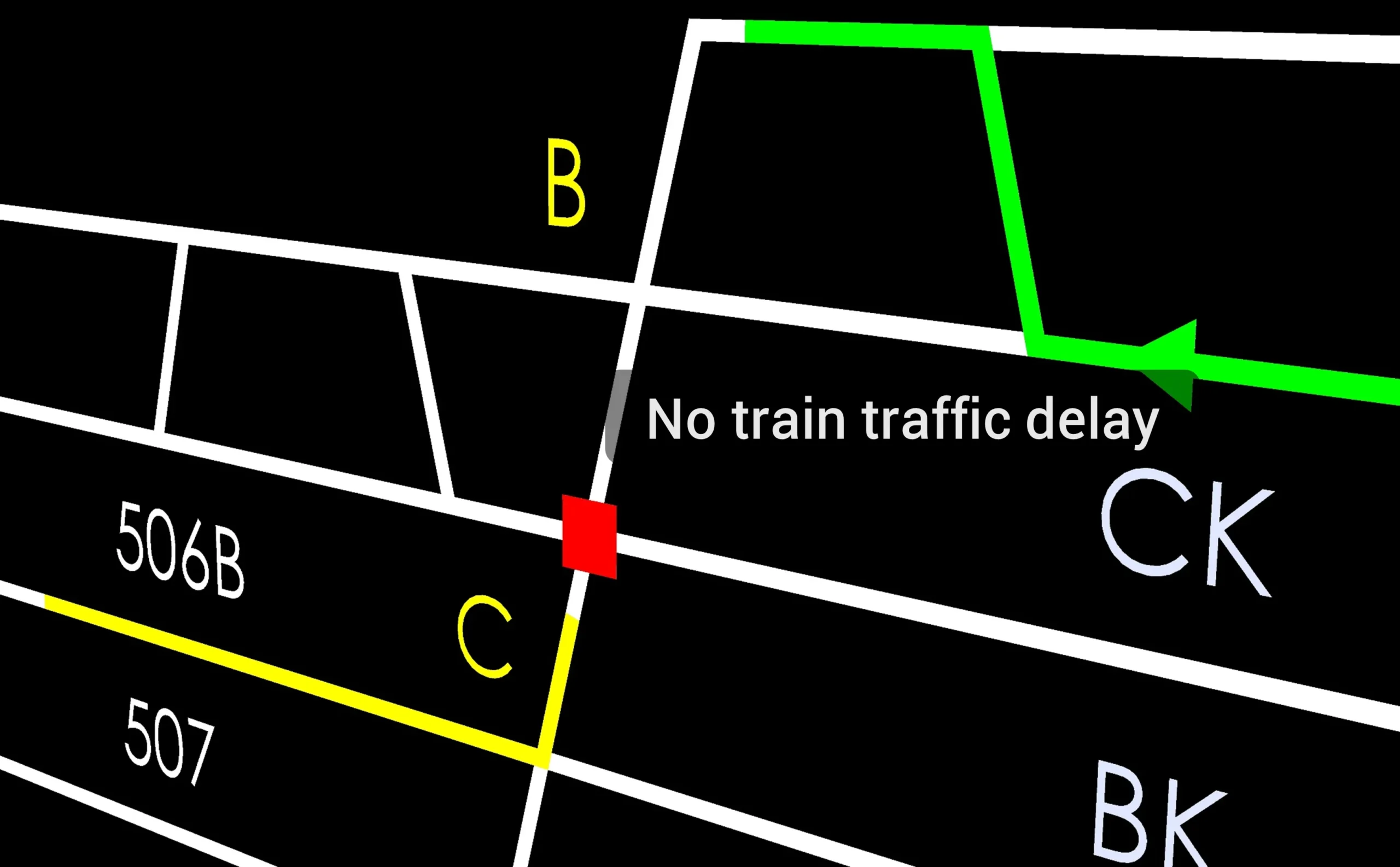

- No more train delays caused by frozen components or switch failures.

Energy efficient Cost effective

- No need for high-energy point heating systems (which typically consume 15kW–30kW per turnout).

- Say goodbye to skyrocketing energy bills and the CO2 emissions they cause.

- No energy wasted heating the surrounding air, a more sustainable solution.

Low maintenance

Lower costs

- No check rails.

- No deformed ballast beds from melted snow and ice.

- No costly system repairs.

- Avoid the high expenses of installing, monitoring, and repairing point heaters.

- Enjoy significantly lower operational costs, especially in winter.

Safe, smooth and silent travel

No gaps in the railhead surface at the frog, reducing noise and vibration.

No risk of derailments or mechanical damage from run-throughs.

- No impact damage to train wheels, making journeys quieter and more comfortable for passengers.

- No excessive mechanical stress in the frog point, resulting in longer-lasting infrastructure.

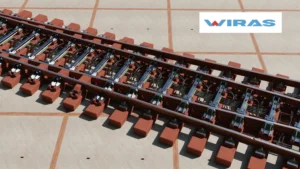

Demonstrators

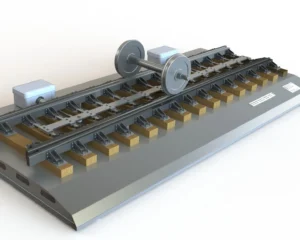

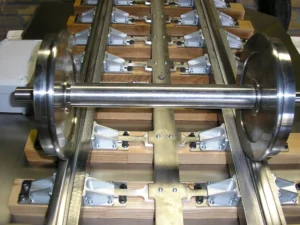

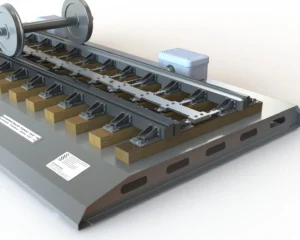

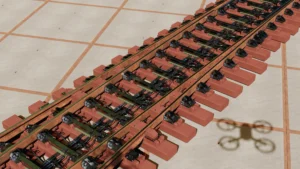

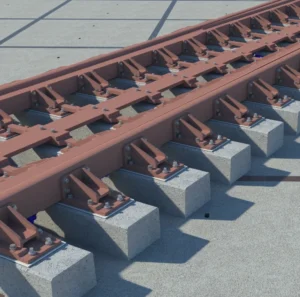

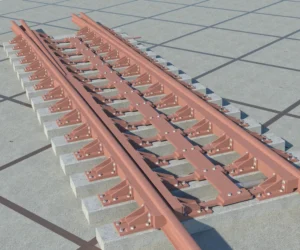

Four full-functional 1 to 6th stainless steel scale-models of the WIRAS Winterproof Turnout and its Winterproof Movable Frog are build as a demonstrators for everyone who want to see the whole design work in real during displaying and demonstrating at indoor meetings, exhibitions and technical presentations. These scale-models are a high detailed representation of the real scale WIRAS winterproof turnout and movable frog and can be easily transported because its weight is only 90kg and its dimensions are 1300mm x 900mm. These WIRAS scale models are both full digital and are programmed and controlled by an intern digital controller, and have high power digital servo’s as actuators.

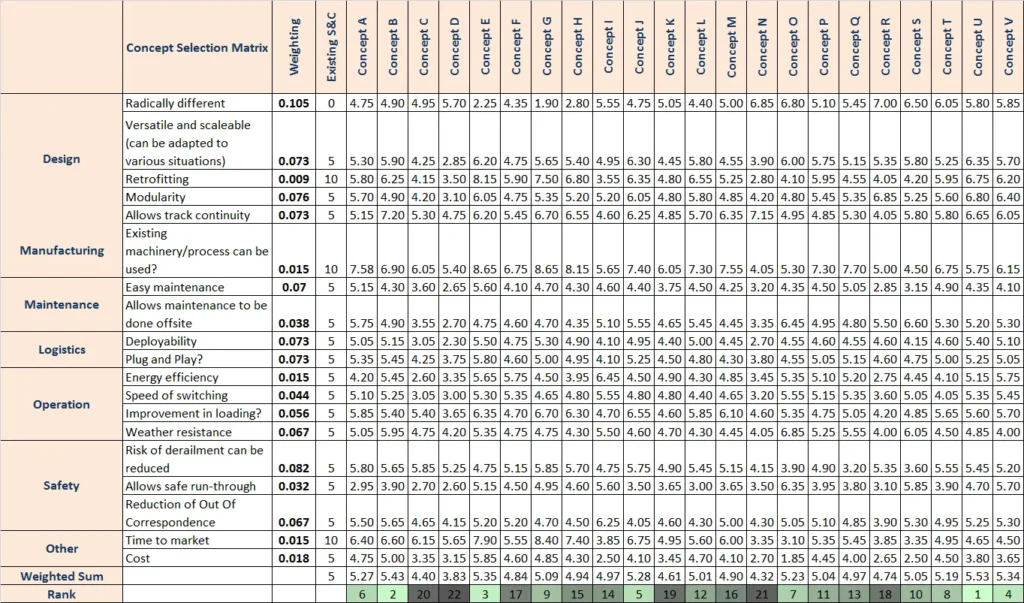

S-CODE

The S-CODE (Switch and Crossing Optimal Design and Evaluation) project is a groundbreaking research and development initiative uniting leading companies, universities, and organizations from four European countries. Funded by the European Commission under the Horizon 2020 programme, S-CODE was part of the Shift2Rail Joint Undertaking, an ambitious public-private partnership driving innovation in the European rail sector.

At the heart of S-CODE lies a bold mission: to develop, test, and validate disruptive new concepts for the mechanical design of rail infrastructure. These innovations aim to enhance capacity, reliability, and safety, while significantly reducing operational costs.

One standout result of the project is the WIRAS – Winterproof Railway Turnout, presented as Concept B in the S-CODE results published by the European Union. Out of 22 evaluated concepts, WIRAS achieved a #2 ranking, reflecting its strong performance and potential. This winterproof switch design eliminates the need for point heating, offering a more resilient, cost-efficient solution for extreme weather conditions.

The S-CODE initiative serves as a model for cross-sector collaboration, promoting a unified approach to the future of rail transport. It identifies and integrates breakthrough technologies such as:

Self-repairing rail components

Super-fast switching mechanisms

Energy-efficient, maintenance-light systems

The project officially began on 1 November 2016 and ran for 36 months, concluding on 31 October 2019. The launch event was held in London on 15 December 2016.

Project Overview

Duration: 36 months

Start Date: 1 November 2016

End Date: 31 October 2019

Total Budget: €5 million

Consortium Partners: 9

Participating Organizations

University of Birmingham

Výhybkárna a strojírna a.s.

Ferrovial Agroman

Rhomberg-Sersa Rail Group

Rail Safety and Standards Board

COMSA

Loughborough University

Brno University of Technology

University of Pardubice

Switch Frog

The Evolution of the Railway Switch Frog

The fixed railway switch frog was invented nearly 190 years ago in the UK. At that time, it was well-suited to a railway system where only one or two trains passed each day, traveling at 40 km/h with axle loads of just 1 tonne and relatively few axles per train. Under those early conditions, the fixed frog was an effective solution that met the technical requirements of the day.

Today, the demands on railway infrastructure are significantly greater. Modern rail networks operate with trains running at speeds up to 130 km/h, axle loads of 22.5 tonnes, and several trains passing every hour. In this high-capacity, high-speed environment, continuing to use the original fixed frog design, which has remained largely unchanged in structure and mechanical principle, presents serious limitations.

The fixed switch frog has become one of the most heavily stressed components in the turnout system. It requires intensive maintenance and frequent inspection. If this design were introduced today, it would likely be considered unsuitable for modern high-intensity rail traffic. Among all elements of a railway switch assembly, the fixed frog point experiences the highest mechanical loads, making it the most expensive part to maintain.

It is therefore quite remarkable that the fixed frog has remained in service for so long. Fortunately, a more advanced solution is available: the WIRAS Switch Frog.

More information can be found in the report Concept B for Switch and Crossing Optimal Design and Evaluation (S-Code) available at:

CORDIS S-CODE Project Results → Documents Reports → High-Level Architecture Design Document

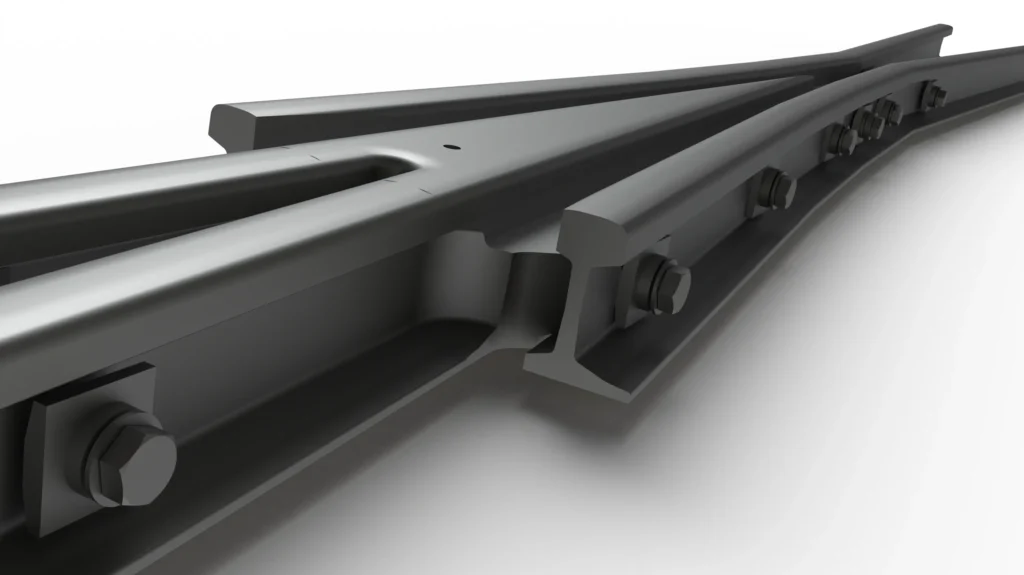

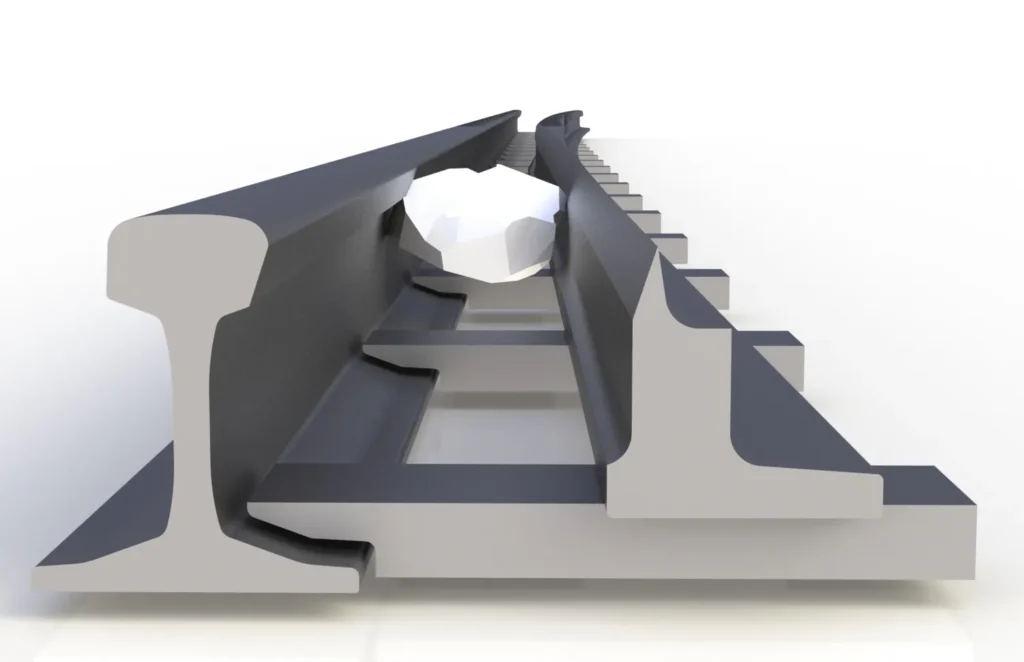

The WIRAS Movable Switch Frog

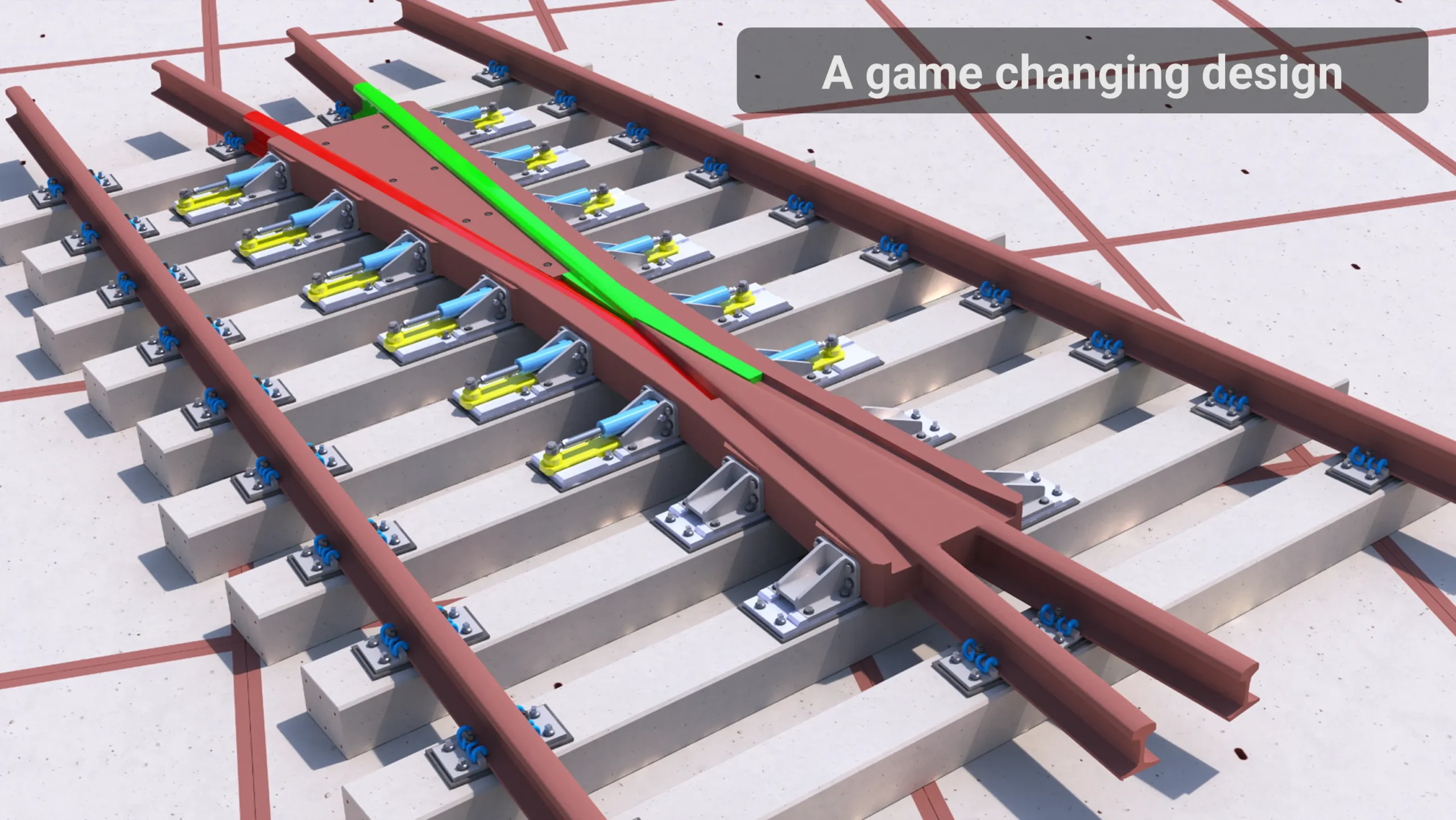

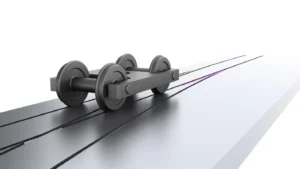

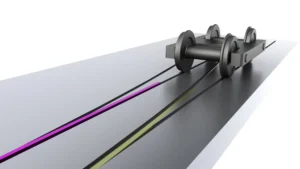

The WIRAS Movable Switch Frog is designed to be part of the WIRAS Winterproof Railway Turnout, especially when constructed to meet high-speed railway turnout specifications.

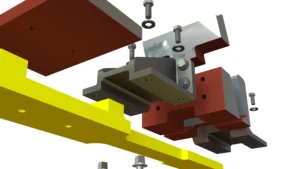

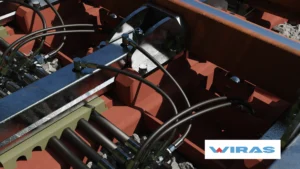

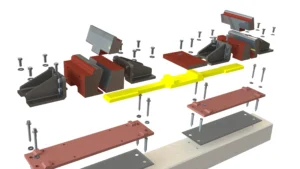

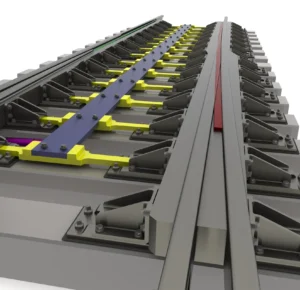

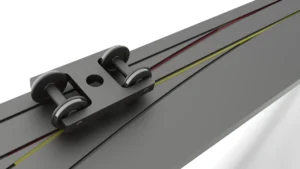

Its operation closely mirrors that of the turnout’s main switch points. The frog legs move vertically and are locked in position horizontally. For securing the vertical movement of both the WIRAS switch points and the frog legs, the system uses advanced self-locking double-acting hydraulic cylinders.

This approach introduces a reliable, modern alternative to outdated designs and represents a significant step forward in railway switch technology.

Self-locking double-acting hydraulic cylinder

Also the advantages for both the winterproof main points and WIRAS movable frog, are the same, in comparisation with turnouts with horizontal moving points and frog-legs : The turnout is winterproof, No traintraffic-delays during winter, No point-heater and frog-heater needed, No high costs for heating-energy, No costs for purchasing, maintenance, monitoring, repairing and replacing of point- and frog heaters, No malfunctioning point- and frog-heaters and because the winterproof movable frog has no gaps in the trainwheel/rail contact surface, it has a very low wheel-rail contact noise. Combining both the winterproof main points and the WIRAS-design switch frog in one turnout, will results in a very valuable and future-proof turnout. The WIRAS Railway Turnout fitted with a Winterproof Movable Frog is very suitable for application in normal train-rail infrastructure, high-speed train-rail infrastructure and in tram-rail infrastructure.

The vertically movable switch frog has no discontinuity in the trainwheel/rail contact surface, and therefore no high material stresses in the point, no excessive wear on the point, no stress cracks and breakage in the point, no excessive material deformations and less wear on the trainwheel/rail contact surface. As a result, less maintenance time is required at the point, enabling greater track availability. No gaps in the trainwheel/rail contact surface also ensures a quieter journey with a higher comfort level for the train passenger, and all that without the need for a point heater, which in turn results in significantly lower energy consumption and CO2 emissions !

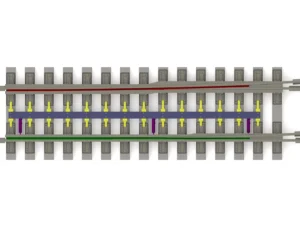

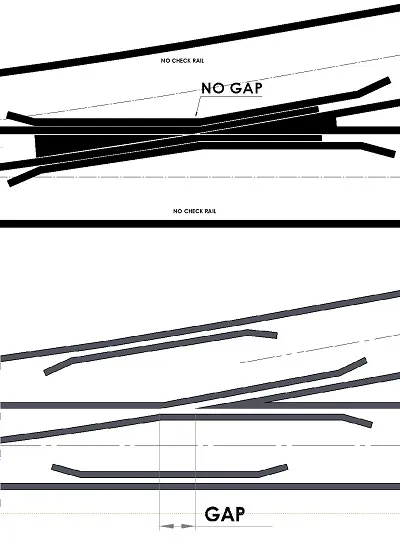

Difference in lay-out of conventional railway frog and WIRAS-design railway frog

Look for the differences ! A minor change in the basic mechanical lay-out of the railway turnout frog (removing the gaps) give significant advantages : reducing material stresses, reducing excessive wear, reducing cracks and material deformations, reducing maintenance to frog-parts and trainwheel contact-surfaces and providing a quieter and higher comfort level for train-passengers and near-railway-yard-resident’s, without the need for point heating causing CO2-emissions!

Maintenance Workers

Maintenance workers of DB Netze inspecting railway switch for mechanical wear and broken parts.

Conventional Railway Switch Frog

Conventional Railway Switch Frog with discontinued trainwheel /rail contact surface (gaps) featured as a standard, causing high mechanical stresses and contact noise-polution.

Conventional Switch Frog with the gaps clearly visible

Conventional Railway Switch

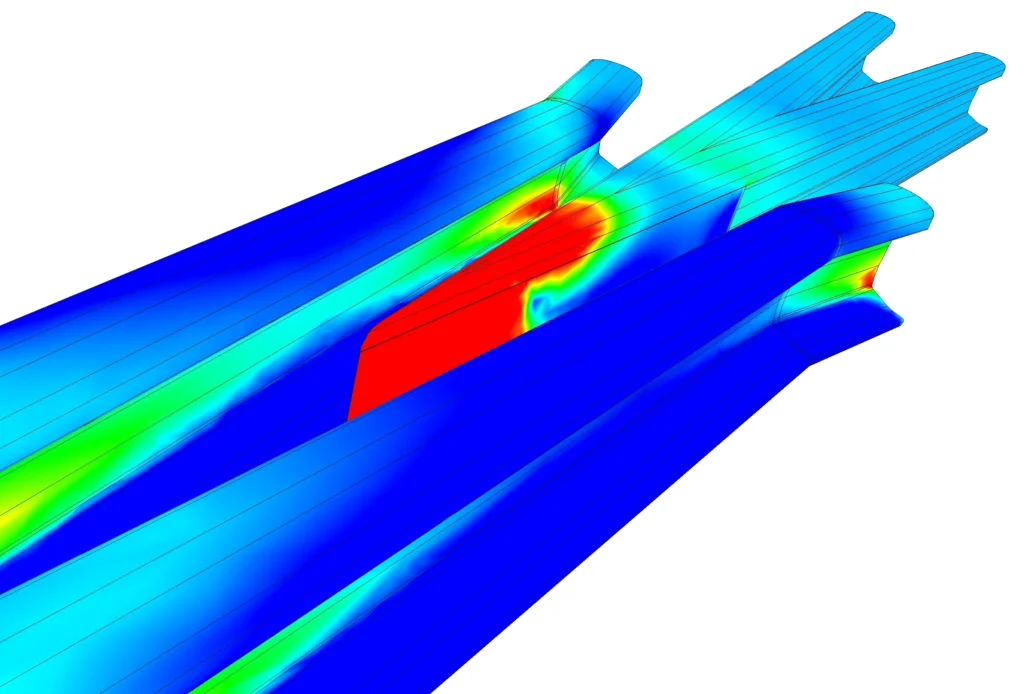

Conventional Railway Switch Frog stress

A 3D-CAD Stress Analysis showing the excessive high stress in the point of the conventional Switch Frog with discontinued trainwheel /rail contact surface (gaps).

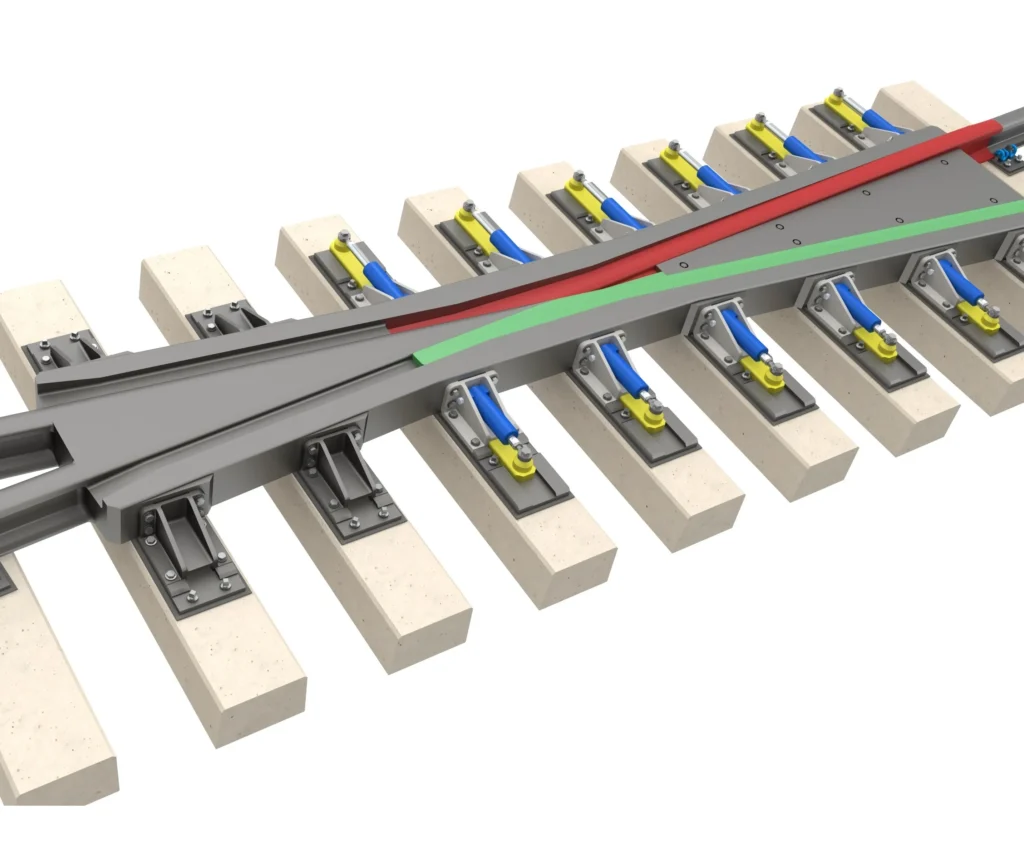

WIRAS Switch Frog

A 3D-CAD model of the WIRAS Switch Frog with vertically moving frog-legs and no gaps in the trainwheel/rail contact surface. Green frog-leg up and in locking position. Red frog-leg low and in locking position.

Close up of WIRAS Railway Switch Frog

Comparisation of Swingnose Frog, Fixed Frog and WIRAS Vertical Moving Frog.

WIRAS Vertical Moving Frog

WIRAS Vertical Moving Frog

WIRAS tram application

Origin

The WIRAS turnout is a completely new railway turnout design developed to operate reliably in winter conditions without the need for a point heating system. This eliminates high energy costs and CO₂ emissions associated with conventional heating solutions.

Frequent winter disruptions caused by malfunctioning turnouts and heating systems have long been a challenge for Dutch Railways (Nederlandse Spoorwegen), often leading to significant train traffic delays. In response, we began developing a new mechanical concept for railway turnouts in 2012. This innovative design avoids the common pitfalls of traditional systems.

Conventional turnouts rely on horizontally moving switch tongues, a design that dates back over a century. Snow and ice can easily accumulate between the tongue and the stock rail, interfering with movement. To prevent this, each turnout typically requires a powerful heating system rated between 10 and 15 kilowatts, which must remain active for several months during winter. The result is high energy consumption and ongoing maintenance expenses.

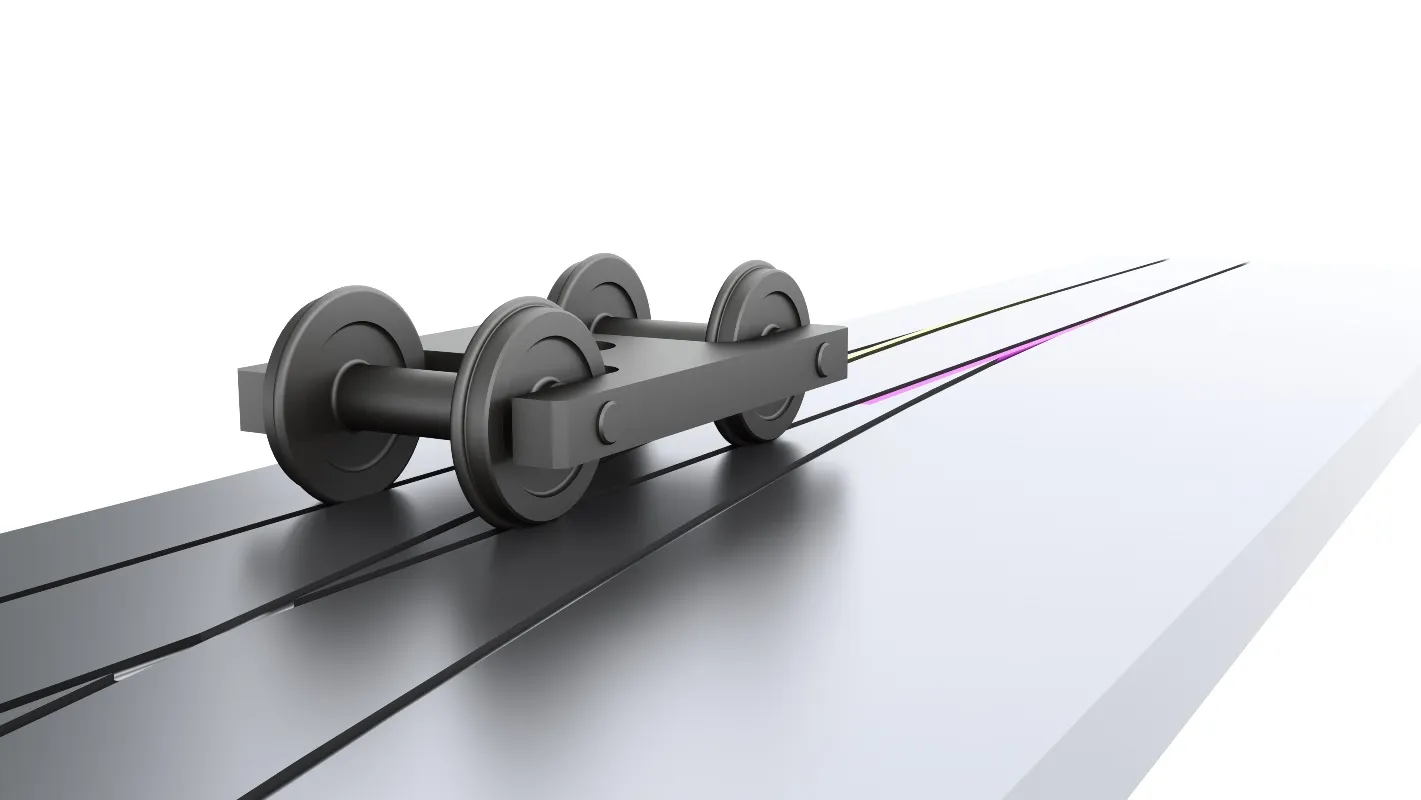

The WIRAS turnout resolves this issue by eliminating horizontal movement altogether. Instead, it uses vertically moving tongues that bend and slide up and down along guided paths. This makes it virtually impossible for snow or ice to block the mechanical operation. As a result, no heating system is required. The vertical movement is driven by hydraulic short-stroke cylinders, and locking is achieved through horizontal mechanical locking bars. These components can be powered either electro-mechanically or electro-hydraulically.

The advantages are clear. The WIRAS turnout continues to function reliably during winter, preventing train traffic delays caused by snow and ice. It significantly reduces operational costs by removing the need for high-power heaters. There is no longer any requirement to manufacture, purchase, install, maintain, or monitor heating systems.

The WIRAS turnout is a direct replacement for traditional heated turnouts and is currently under discussion in the Netherlands with leading turnout manufacturers such as Vossloh and Voestalpine, as well as Dutch Railways (NS) and ProRail, the national railway infrastructure authority. The design is patented and suitable for applications in train, high-speed train, and tram infrastructure.

The WIRAS turnout offers a reliable, cost-effective, and sustainable alternative for modern rail networks operating in all weather conditions.

High energy consuming point heating systems not needed anymore

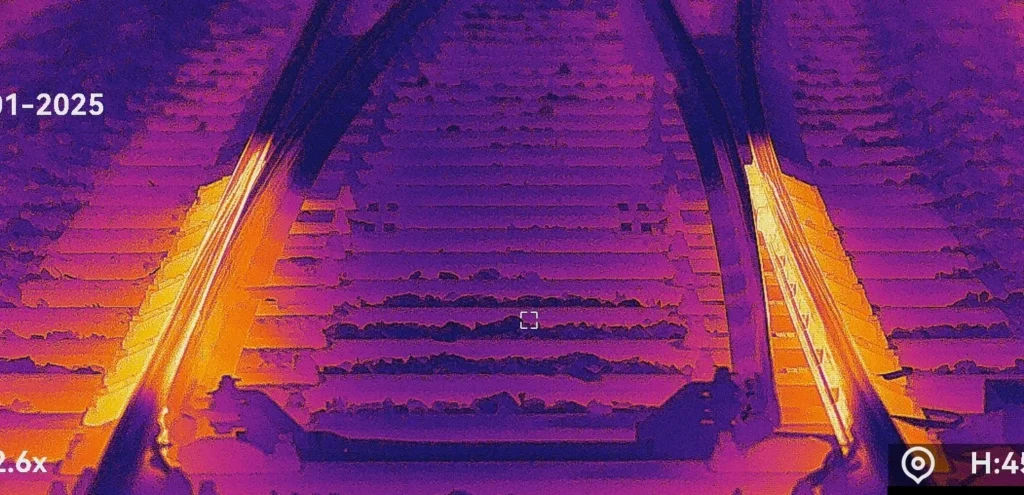

Few realize how easily the operation of a railway switch can be disrupted by something as simple as a chunk of ice falling from a train. When ice lands in the mechanism of a switch, it can block movement entirely. Melting that ice with a point heating system is not quick. The contact surface between the ice and the steel rail is small, and the rail itself is not especially warm. As a result, the melting process is slow, often far too slow for passengers and freight that rely on timely arrivals. This delay directly impacts track availability and network efficiency.

The problem is especially common at the switch point itself. Here, the continuity of the rail head is interrupted, creating a small vertical gap that causes a vibration in passing trains. That vibration often shakes loose ice that has accumulated on the train, causing it to fall precisely where it can do the most damage, into the critical moving parts of the switch.

These issues have been tolerated in railway operations for far too long. But today, better solutions are available. With modern switch technology designed to prevent such disruptions entirely, it is now possible to eliminate this long-standing weakness from rail infrastructure.

Closed switch tongue

Open switch tongue with trapped piece of ice, disabling the correct working of the switch.

Cumulation of snow on a locomotive bogie

Switches jam from cumulated ice falling from trains

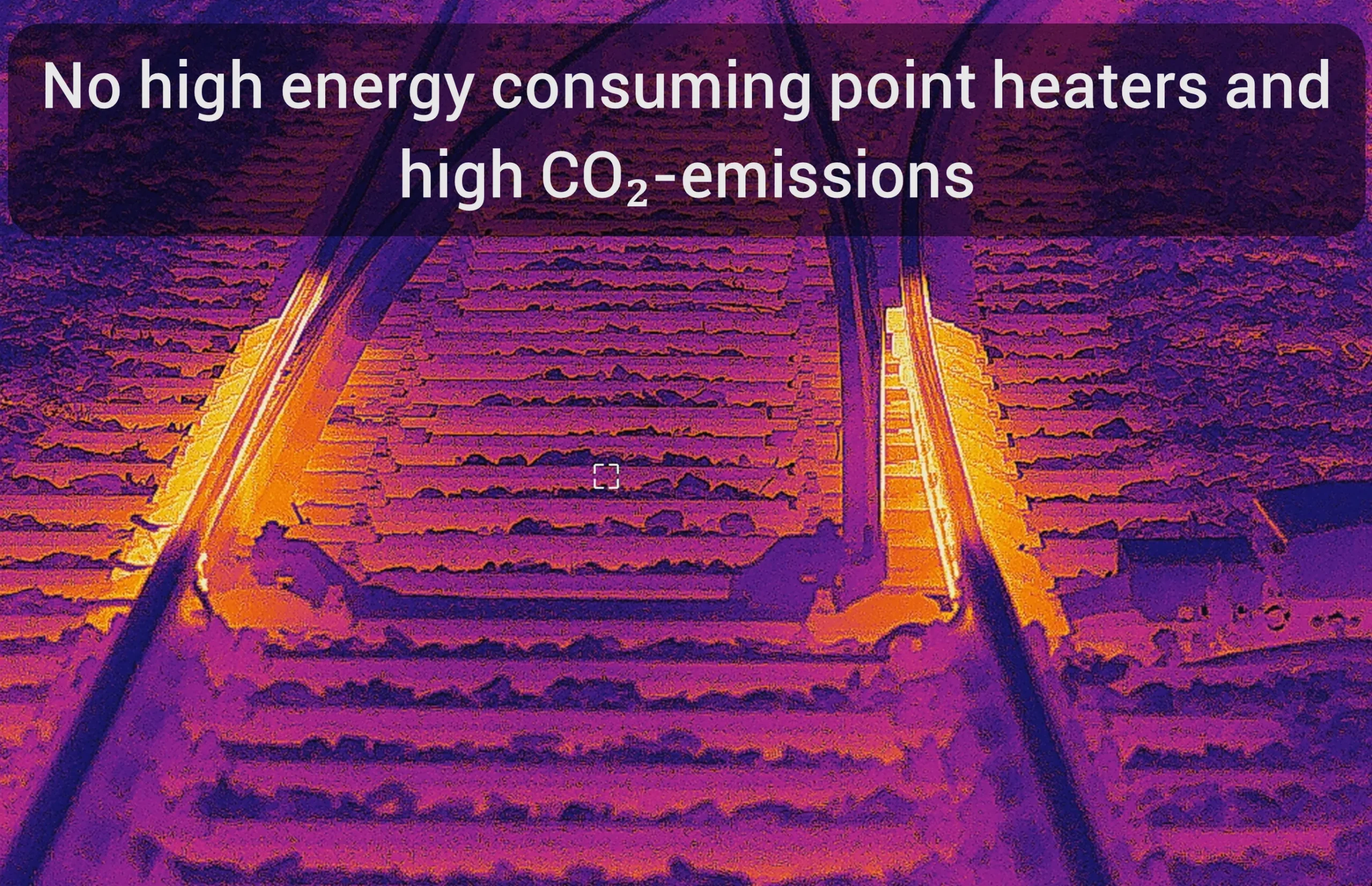

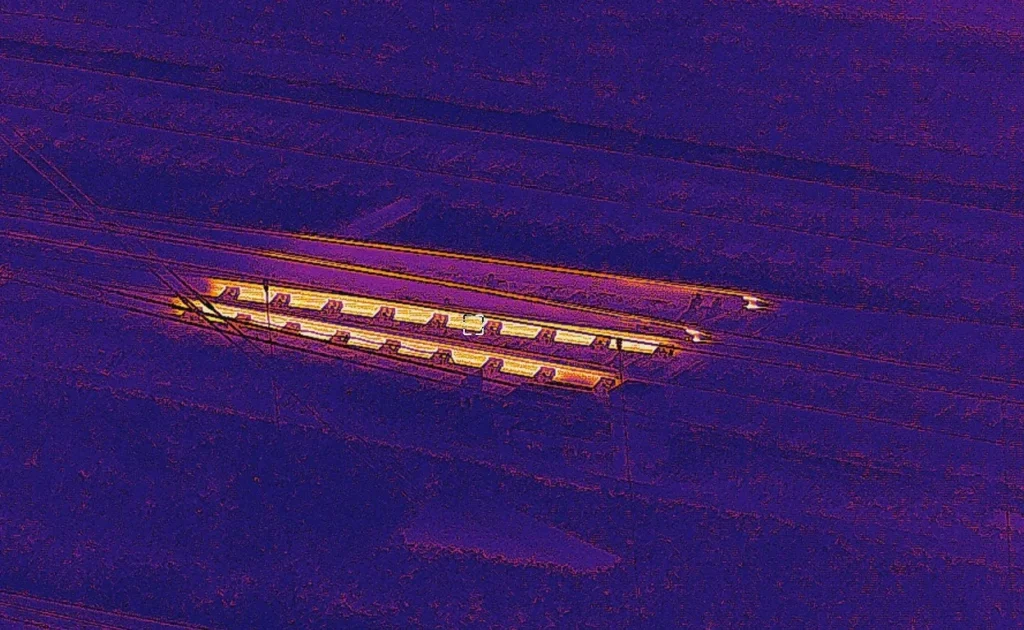

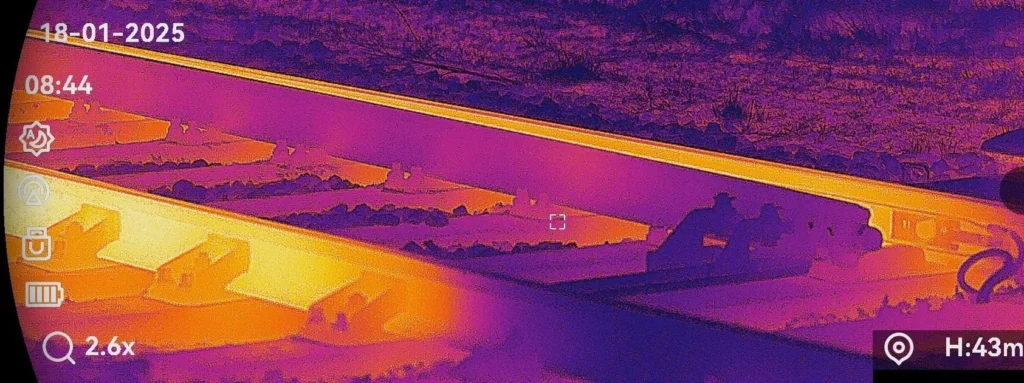

High Energy Loss, Low Efficiency

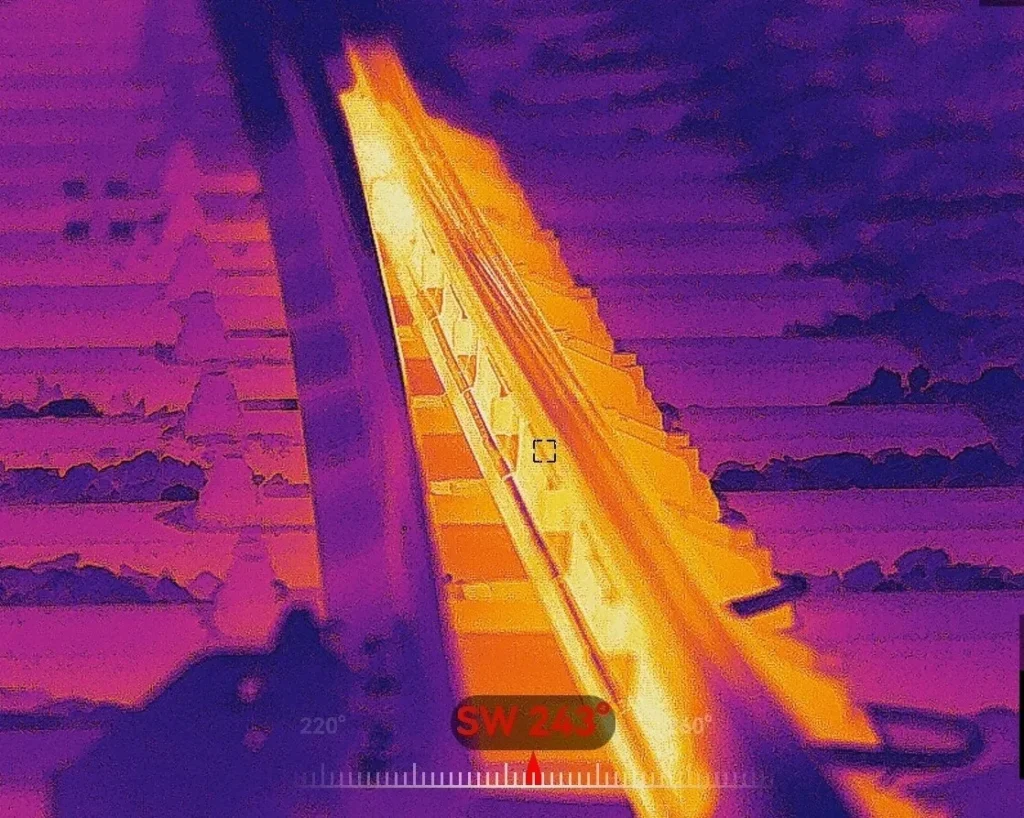

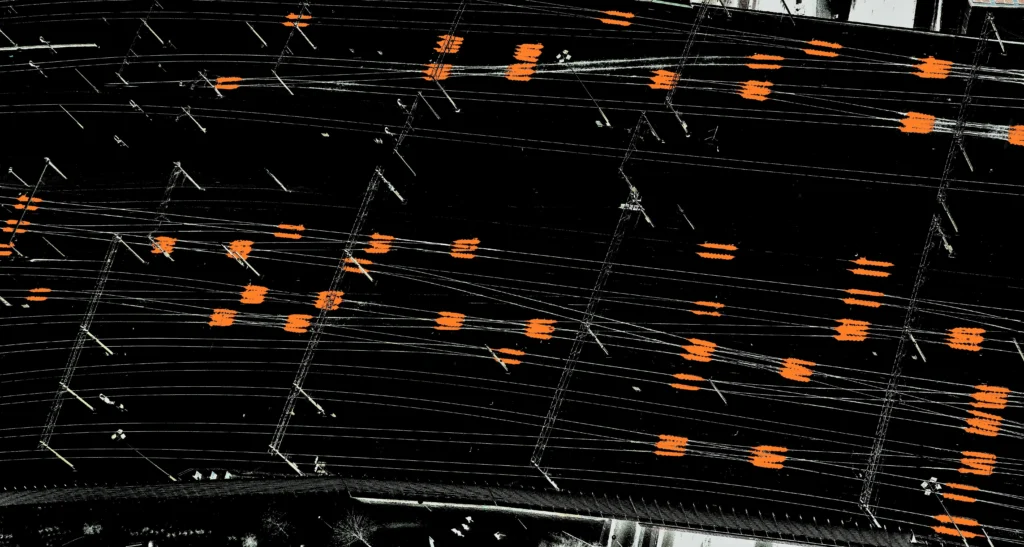

To remain operational in winter, each turnout point requires 15…30 kW of heating power yet a staggering 99% of this costly energy is wasted, simply heating the surrounding air instead of the mechanism itself.

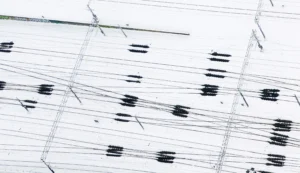

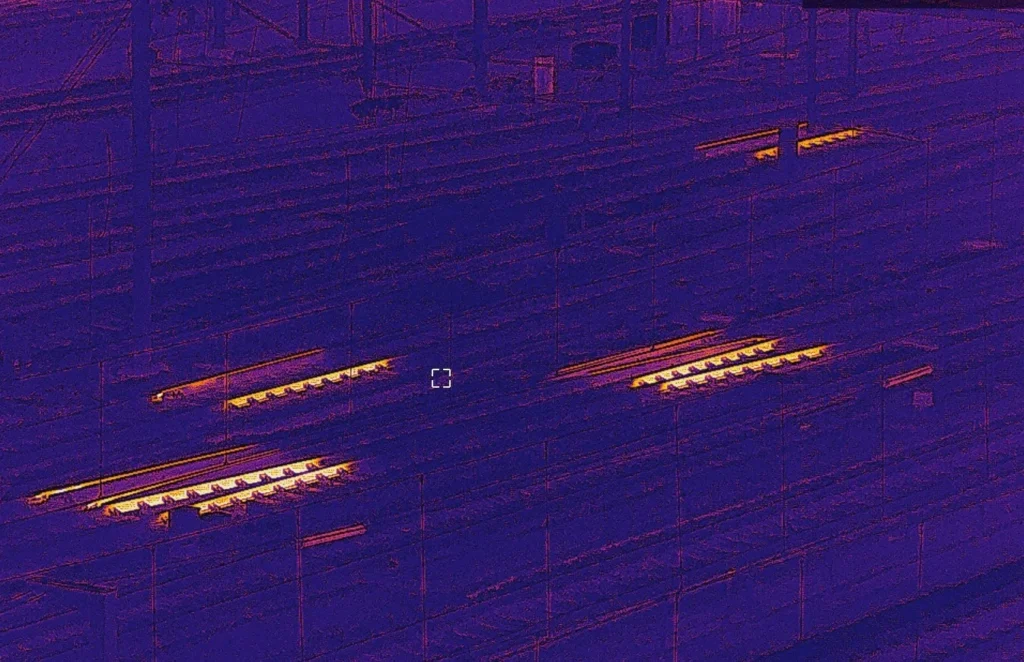

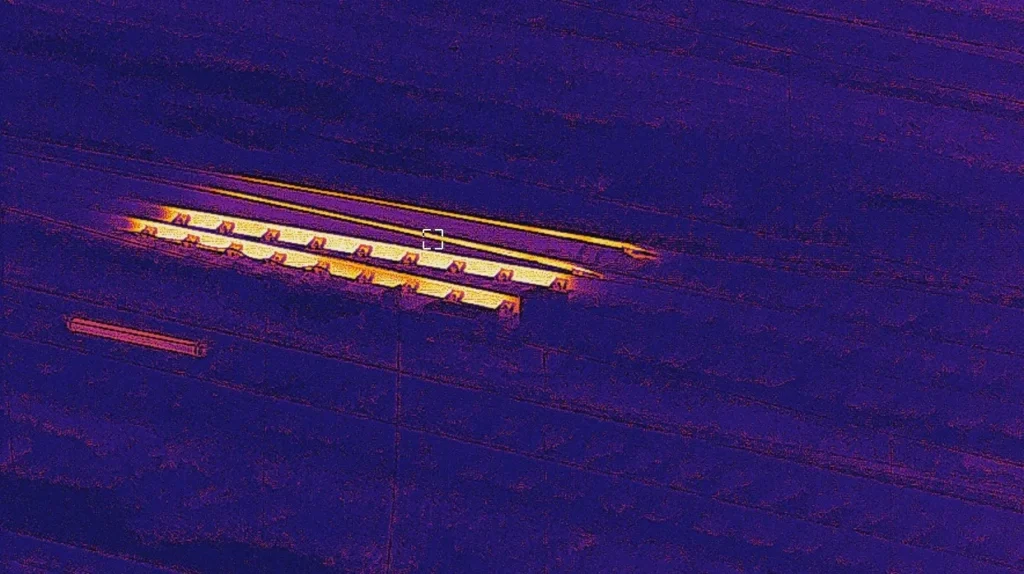

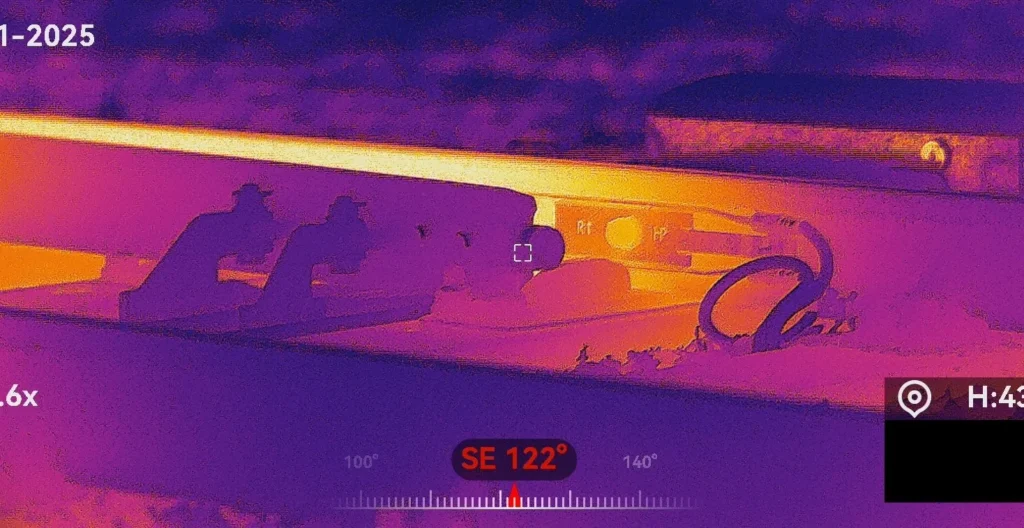

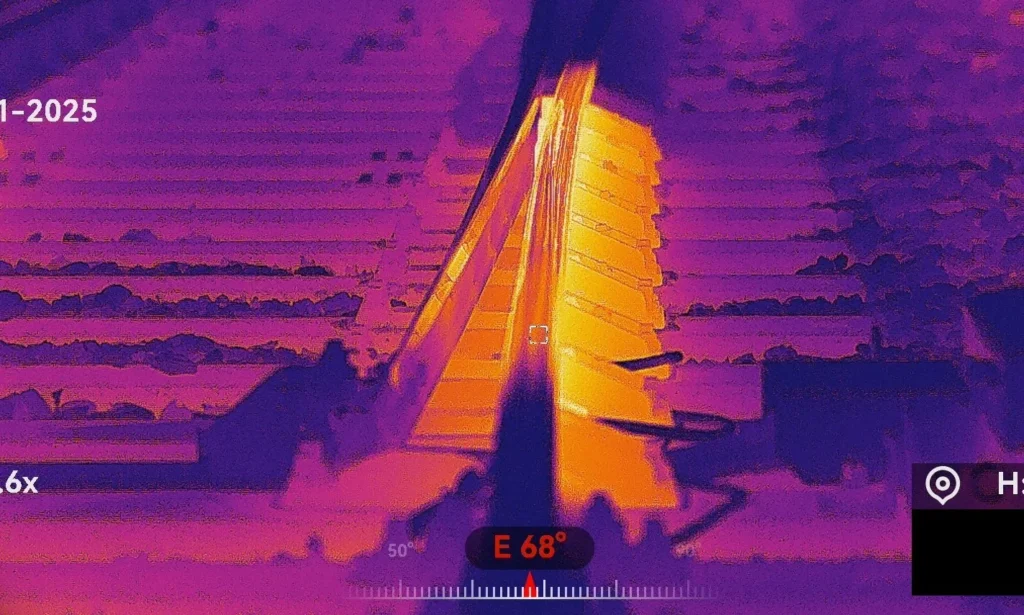

Thermal image of railway yard

Huge Energy Loss You Can’t Ignore

You don’t hear it.

You don’t see it.

But in winter, it’s running 24/7.

Railway point heating consumes up to 10-15 kW per turnout, yet 99% of that energy is wasted. It heats the air, not the mechanism. Still, reliability isn’t guaranteed.

Modern turnouts remain the weakest link in winter time operations.

Extreme cold and blizzards easily overwhelm today’s point heating systems.

A Smarter Switch for Winter

There is a new turnout design with a radically different mechanical layout.

It stays fully functional in harsh winter conditions without any heating system.

No heating means:

Zero CO₂ emissions

No energy bills

No winter failures

While others burn energy to fight the cold, this WIRAS solution simply doesn’t need to.

Efficient. Clean. Reliable.

Winter-proof by design.

Thermal video of pointheating in a railway yard

Thermal image of pointheating

Point Heating and Its Hidden Impact on the Planet

Point heating systems contribute to global warming in two major ways:

CO₂ Emissions:

Every kilowatt-hour of electricity used produces about 0.7 kg of CO₂. That means each turnout emits up to 112 kg of CO₂ per day.Massive Energy Waste:

A typical point heating system uses 10 to 15 kW of power, but only 1 percent of that energy heats the switch. The other 99 percent warms the surrounding air.

In the Netherlands alone, point heating systems waste an estimated 1,080,000 kWh of energy every 24 hours during winter.

That’s energy lost.

That’s CO₂ added.

And it’s happening every single day.

* Mandatory field